Slotted Machine, Self-Tapping & Thread Forming Screws

As an experienced wholesale distributor of Metric Fasteners and industrial components, Metric and Multistandard Components Corp. has outstanding customer service and superior technical knowledge for all your slotted machine screws, self-tapping screws and thread forming screws needs. With strategic warehouse placement across the US, MMCC has the capability of delivering product to every US city within 2 business days. Immediate product availability offers you the efficiency and reliability you need in a trusted fastener distributor.

Metric & Multistandard Components Corp. supplies several types of slotted machine screws, self-tapping screws and thread forming screws in a variety of different head styles, drive types, and materials including:

Metric & Multistandard Components Corp. supplies several types of slotted machine screws, self-tapping screws and thread forming screws in a variety of different head styles, drive types, and materials including:

Common Slotted Machine Screw, Self-Tapping Screw Types & Thread Forming Screws

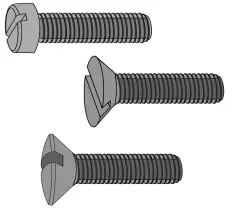

Slotted machine screws, self-tapping screws and thread forming screws are versatile screws for assembly and fastening applications. Application uses can vary but slotted machine screws, self-tapping screws and thread forming screws can be used for wood, metal, and concrete applications.- Slotted Machine Screws. Externally threaded fasteners that are used with a threaded nut or tapped hole.

- Machine Screws are generally only available in diameters up to M10 and not normally used in any high tensile applications.

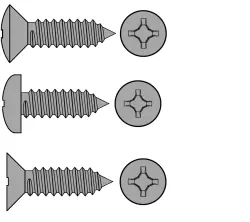

- Self-Tapping Screws. Externally threaded fasteners that will make their own thread as the screws are driven into the material. They have a coarse thread on them and can only be replaced with a similar style screw. Self-Tapping Screws are sometimes referred to as Sheet Metal Screws since they are most often used with sheet metal.

- Thread Forming Screws which will displace material to form a thread as it is driven into the material. They are also called Thread Rolling Screws. These screws do not create any chips and can be used in blind holes or through holes.

- Thread Cutting Screws which will cut the material that it is being driven into, creating a new thread.

- Thread Cutting Screws and Thread Forming Screws can help reduce production costs since they do not require a pre-tapped hole or nut. Since these screws are creating their own threads, there will be less of a gap between the male thread of the screw and the internal thread of the hole which leads to a tighter fitting screw that is less apt to loosen. Since thread cutting screws and thread forming screws create a machine screw thread if they need to be replaced, these screws can often be replaced with a regular Machine Screw.

- Pan Head Screws. With a broad head and round edges, pan head screws are non-countersunk screw heads ideal for metal-to-metal applications or where flat-bottomed screws are required.

The best type of tapping screw to use will depend on the application.